Progress, and Cruiser Karma

Update on the 4 Critical Projects . . .

Rig. Done.

Thru Hulls. Done.

Engine/electrical. Done. (There’s a video on my Instagram of the purring engine. I promise!)

Rudder. Umm . . .

Coat 8 of glop on the rudder cheeks.

A couple of weeks ago, a friend-from-the-internet asked me if I had ideas about how to get from Zimmermans Marine, about a half an hour away from Deltaville, to the Richmond airport. She and her husband were hauling the boat out at Zimmermans and flying home to the Pacific Northwest. “I’ll take you,” I responded. We had the most lovely time chatting and swapping cruising stories on the hour and a half drive to the airport, and we all left promising to share an anchorage in Maine later this summer. Before they got out of the car, they both kind of looked at me. “Did you have business to do in Richmond? Because it was really nice of you to drive all this way!”

Cruiser Karma. Paying it forward. Helping when you can because you know at some point, you’ll also need help. It’s one of the major perks of being in the cruising community, as far as I’m concerned.

Met on the internet, now friends in real life!

What does a morning on 64 have to do with our rudder progress? There’s that cruiser karma thing again.

Our buddies Dave and Carol, who once upon a time loaned us the use of their rental river house, have built a new house on Dividing Creek, just over the Rappahannock River from the boatyard we’re in. On Monday morning, while I was sanding the rudder in preparation for barrier coat, my phone basically blew up with texts and calls. Jeremy commented, “Dave and Carol really want to get in touch with you.” He’d been contorted all different ways in the forepeak, installing the windlass power controls.

The phone rang again. Dave. “Hey. It’s miserably hot out. I’ve got all day free, and all of tomorrow morning, if you want to come up here and use the air conditioned workshop for that vane project. I can help.”

The wind vane, our mechanical self-steering system, is possibly the biggest hold up to launch. It’s part of the rudder project, because the trim tab part needs to be affixed to the whole length of the rudder. And the trim tab part is all we’re focused on; the wheel and sail that are above the waterline can be tackled later.

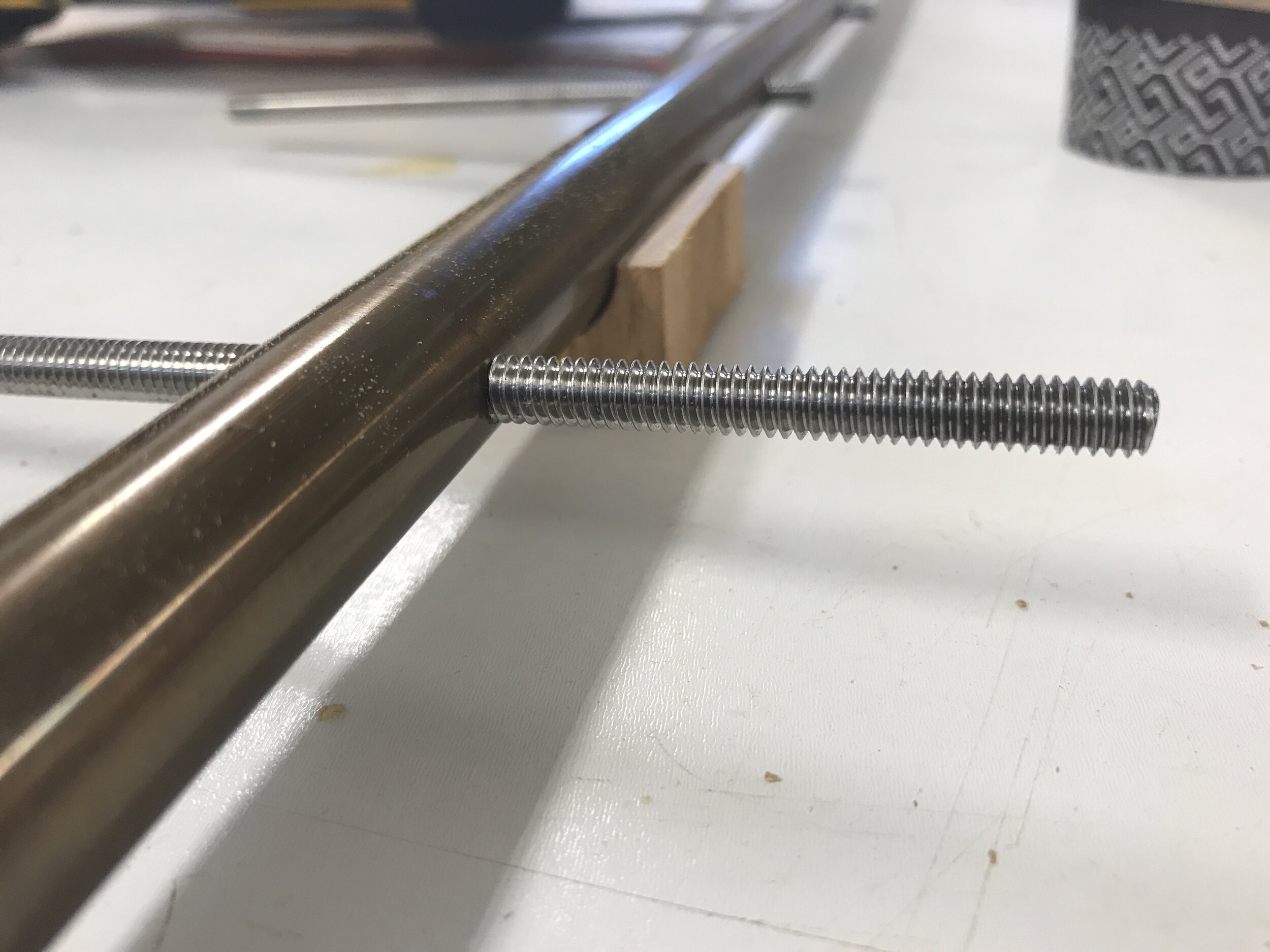

The trim tab is made of wood. Specifically, 2 pieces of iroko that need to be shaped and have a channel cut into them for the bronze shaft to fit in. Essentially 2 clamshell halves that need to be shaped. The 1” diameter bronze shaft needs to have 7 holes drilled into it, and each of those holes needs to be tapped for the all-thread rods that will help keep the trim tab straight and centered. Those all-thread rods need to be cut to the right length, and the sharp edges filed down. How to do all this work with makeshift tools is a real question.

When Jeremy, sweat pouring down his face in the 93 degree windless heat, heard Dave’s offer, his eyes lit up. Dave is an experienced wood worker with a shop full of tools.

We pulled up to the doors of the garage at about 3. Dave quite literally dropped what he was doing and immediately got to work. I wish I had photos of the bare wood pieces that it all started as.

By 7 pm, the wood was planed, rough shaped, grooved out for both the shaft and the all-thread. All shaft holes were drilled and tapped.

And by 4 pm the next afternoon, we’d glued up the major part of the trim tab for the self-steering vane.

Dave’s skilled help, combined with the right tools and an air-conditioned space, made an INCREDIBLE difference in the progress that could be made. It really feels like we’re a full week closer than we had thought we’d be. Is it possible we could launch this week? UNREAL!

Dave and Carol are cruisers, in case you couldn’t figure that out. The helpfulness of the community never ceases to amaze me.

Update as of Sunday morning, July 4. Independence Day, for Americans. The vane blade is done. Jeremy (with Dave’s help) has built the “tiller clutchie thing” (see Jeremy’s Instagram) and is ruminating on how to build the tiller lock mechanism (which is the only part of this whole design that looks crude and Rube Goldberg-like - there MUST be a better way).

We’ve rolled on 4 coats of barrier coat. Bottom paint is next. While we wait to be able to bottom paint, Jeremy is building the propane boxes using Dave’s table saw and I’m making ciabatta rolls. This afternoon, we’ll return to Deltaville, I’ll slap a coat of bottom paint on the boat, and Jeremy will work on protecting the underwater metal parts.

Working in the workshop applying barrier coat.

Launch is close enough that we’re talking about what we need to get from storage to be able to anchor that first night, and how we can jury rig a makeshift head to pull that off. We’ll be headed to a friend’s dock on Fishing Bay for the final push of “get her seaworthy” projects, but we both really want one night at anchor to savor. Are we REALLY that close???